new pulp

This is where we post all things new going on in pulpland. We’ll be updating often so stay tuned or sign up for our newsletter below to receive the occasional update. Everything we post on our new pulp page usually ends up in our pulp pages section (see above) so feel free to jump in there and have a look!

This Week’s Featured Pulp Improvement

Pulp Kitchen

Pulp Bath Reno 2

As often happens when doing the home remodel thing, you get inspired to do something other than the current project you are working on, especially if it is not a huge time endeavor and it can have almost instant impact. This week I give you a little of that, aka, Pulp Kitchen backsplash tile!

Our kitchen, while very nice, never had a backsplash behind the stove. Just plain old painted sheetrock so it had been on our list to do at some point, only a matter of finding the perfect tile to complement the stone counter and above cabinetry. Enter a trip to Floor and Decor, a square 5”x5” ceramic tile and we were off to the races. Cleaned up the tile cutting machine, made a few cuts and a couple hours later, we were about 85% complete. We’ll finish it up this weekend (see adjacent pic)!

Back on the Pulp Bath Reno 2, continuing on with the necessary but not extremely exciting pic worthy infrastructure type tasks, in this case, the bath exhaust fan install! Now, you might ask, what’s the big deal with that? You just hang a fan and run some duct outside, right? Well, not so fast my friends. Remember, this is a 2nd floor (of 3 floors) bath room and we had no desire to pop a hole in the side of the house for a vent which would have just looked weird, so where do we go with it? In our case, we had added an exhaust fan to the above Pulp Bath Reno 1 which we ran up and through attic and then out of the roof while we were getting the shingles replaced (nice roof vent, looks cool). Now, also above the Bath Reno 2 is a good size store room which actually has a little box out of the vent that runs up from the bath room in a wall that forms one side of the 3rd floor bath, providing a path to follow to get into attic, just had to connect everything, so out came the hole saw (4 1/4” to allow 4 inch duct to comfortable pass through) to cut through 2nd and 3rd floor ceilings. With holes in place using a solid metal duct in 3rd floor storeroom and then a flex duct connect to new fan in restroom. We’ll cut the 3rd floor bath exhaust flex duct, install a 4” hard duct Tee in line and then pop a couple 4” PVC check valves on the connections from each of the bath rooms allowing for the use of one single vent through roof (no additional holes through exterior required)!

I did mention last week, that we would be installing a new light fixture in the living room (we had put a hole in the 2nd floor bath floor to mount a junction box) and install we did. Then we added the G9 plug bulbs that were required and guess what? Not happening, at least for the living room. We were looking for a nice warm feeling light, went with the warmest white bulbs available and it just ended up being too cool (and not the good cool) color wise in combo with the hanging glass pieces that were part of the fixture (there is a pic below). So, we’ll move this fixture into another room and new one is on the way, feeling good about it!

The Progress pics below. See you next week!

Pulp Improvements

The 257 Project

Most Recent Pics for Sale

The 1800 Project

Here’s the trailer to the exciting new movie coming out this summer (okay, so maybe not really a movie, more a couple long form video’s to document the start to finish of this project)! Truth is, had a little fun with a movie trailer template they have and this is the “story” of the 1800 Project to date. Enjoy!

Nothing at All

A long time ago, in a small apartment in New York City, I was listening to a Prince song, simply called “7” and I was very much getting into the sound of the guitar playing, and what I perceived as an “open” chord strum, aka, just hitting those strings with no fingers applied (forgive me if that was mistaken). I tried to work that into something, and came up with a riff that I thought was pretty catchy. Not 100% sure what mood I was in at the time but decided that “you don’t need Nothing at All” was a good premise and ran with it. Years later, and also during the pandemic, decided it was a good time to rebuild it. Got busy with my wonderful musician friends and a new version it was.

Hope you enjoy!

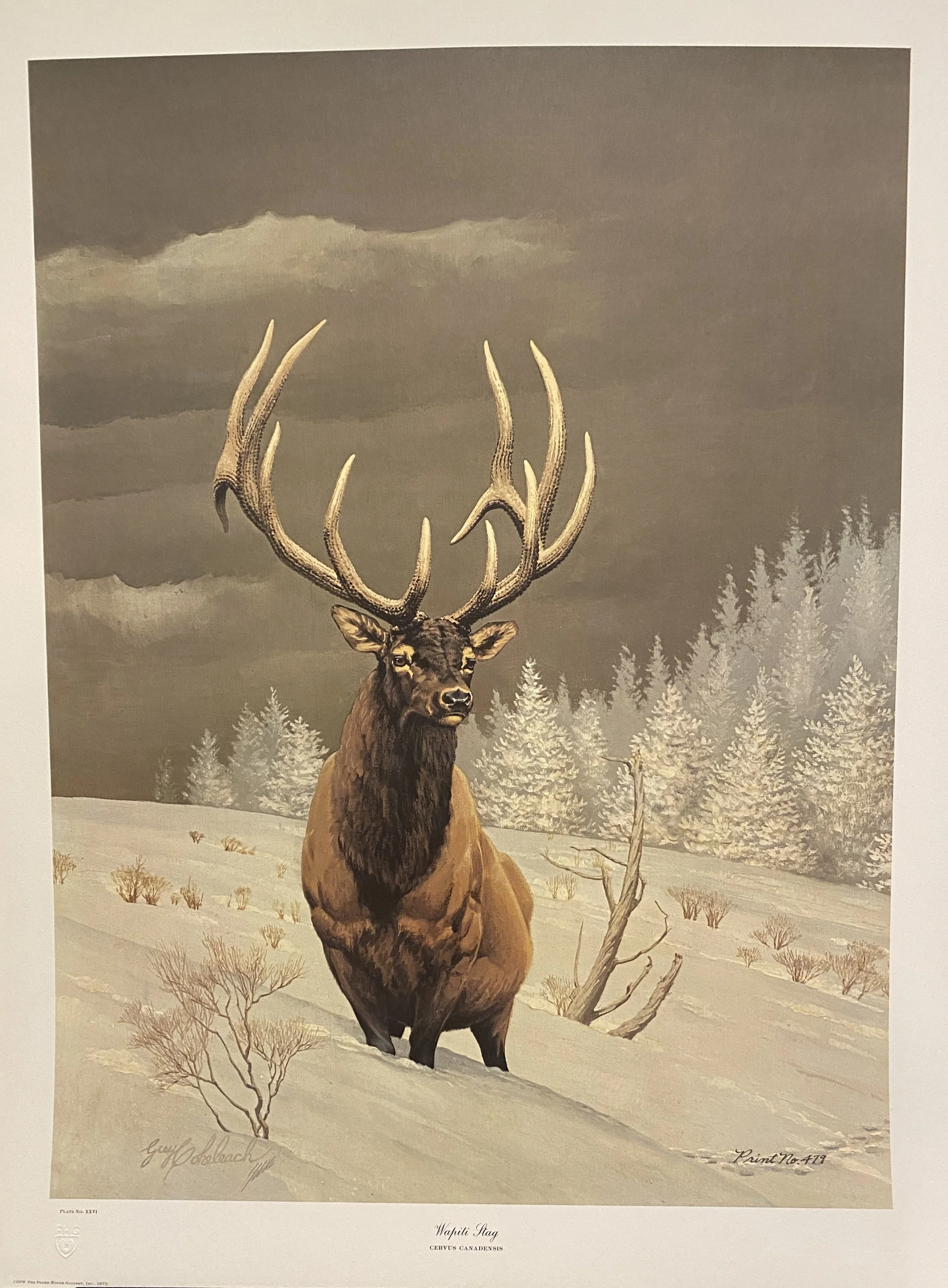

The Ray Harm and Guy Coheleach Limited Edition Prints Prints

We recently mentioned that we had been gifted a fine collection of Ray Harm and Guy Coheleach “limited edition” art prints which we intend to eventually sell here from the website (will be setting up a page in our shop collection). Currently doing a complete inventory of what we have and documenting all of that. Wanted to share a little taste of what we are talking about so will feature a pic or two each week until we get that shop page up and running. This week’s sample print below!

Wapiti Stag